|

Tech Pro Blades Support

This page has information supporting our Tech

Pro Blades product.

Specificatons

Tech Pro blades are PVC covered wood blades

and come in five colors and three sizes.

Colors: White, Yellow, Red, Black

and Blue

Sizes: 315mm, 325mm and 335mm

Airfoil: Fully symmetrical

Configuration: Constant cord 31.5mm

wide with a weight range of 16.5 grams to 19.5 grams

Weights: 2 lead strips along outer leading

edge totaling 3.1 grams

Wood Species: Alder

Maximum safe RPM rating is

2400 (See Testing section

below)

Construction

The blade root has both the top and

bottom plastic grips glued on and screwed in place.

Each blade is formed from a single piece of wood and sanded smooth.

Blade root construction

Top side blade tip

Lead weights (3.1 grams) are installed on

the underside (glued in)

Testing

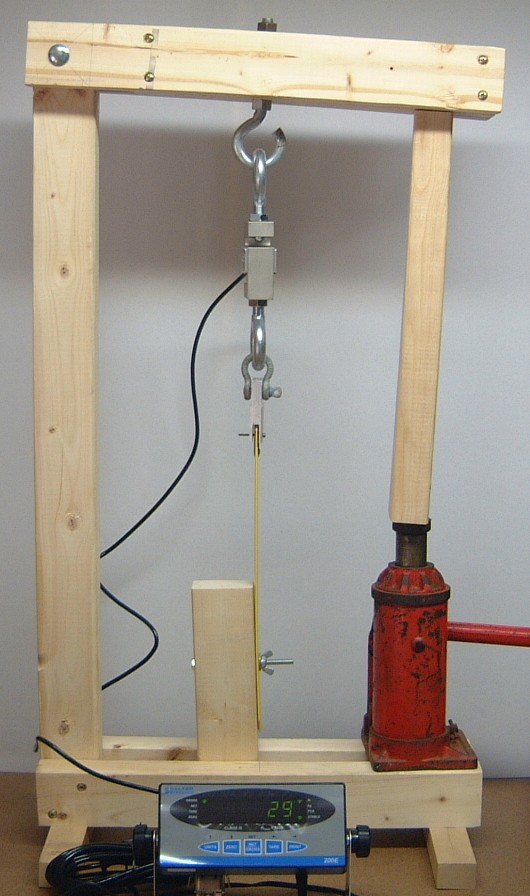

We built a test fixture called the

"Blade Ripper" to determine the force required to pull the blade off the

blade holder bolt.

The jack simply applies force through the blade which is measured by a

digital force gauge (scale). The scale has a

peak hold function which records the maximum force before the blade gives

out.

Blade Testing Results

Our testing has shown that the Tech

Pro blades and the Align Pro blades are about the same strength.

For each, the minimum breaking force was about 212 pounds and maximum was

about 233 pounds.

We can say that the static breaking force is above 200 pounds for both

brands of blades that were tested.

Note: These numbers are based on a total

sample of 20 blades tested.

Blade Force Calculations - Centrifugal Force

The force applied to the blade root (behind

the bolt in flight) can be calculated with the formula below.

Fb = W / G x Ω² x Rcg

Where

Fb is the

force in lbs

W is the weight of the blade in lbs

G is the acceleration of gravity

= 32.2 (ft/sec)²

Ω is the rotor speed = RPM x

2π / 60 radians/sec

Rcg is the distance from the center of the main

shaft to the CG point on the blade.

| Example 1 Given:

325mm blade, 19 grams, RPM = 2400

W

= 19 / 454 = 0.041 lbs

Ω = 2400 x 6.283 /

60 = 251.33 radians/sec

Rcg = 0.64 ft (for a TRex 450 with

plastic head)

Fb

= 0.041 / 32.2 x (251.33)²

x 0.64 = 51.47 lbs

The Force at 2400 RPM is about 52 lbs |

|

Example 2 Given:

325mm blade, 19 grams, RPM = 3100

W

= 19 / 454 = 0.041 lbs

Ω

= 3100 x 6.283 / 60 = 324.62 radians/sec

Rcg = 0.64 ft

(for a TRex 450 with plastic head)

Fb

= 0.041 / 32.2 x (324.62)²

x 0.64 = 85.87 lbs

The Force at 3100 RPM is about 86 lbs |

Summary

The testing was performed on a relatively

small number of blades (20) so there may be smaller minimums and larger

maximums

with respect to the breaking force. There is no practical way to

completely test these blades without damaging them.

Wood is a natural material that is not homogeneous. Defects can be

present which weaken the blade and cause it the break sooner.

The centrifugal force is not the only force on a rotor blade although it

is the major one. These other forces are dynamic and vibratory

in nature and although smaller in magnitude they are considerable since

they have a jack-hammering effect.

A safety margin must be allocated for them.

All wood blades deteriorate (lose strength)

with use. The harder they are worked the weaker they will get.

The centrifugal force is not a linear function

with respect to RPM, it is exponential. If you double the RPM you

will quadruple the force.

These blades are made in a factory overseas.

We have no control of production or quality control. Because of

this, we cannot be held

responsible for any damages or injuries. Use

these blades at your own risk.

Given all of these factors, we recommend

that the maximum RPM ratings on these blades be followed for safety.

Going forward

Our blade testing fixture can handle up to

3000 lbs of force which is limited by the scale. We would like to

test some of the

composite blades out there like the SAB etc. Also, it would be

informative to test some heavily used and abused blades.

Accurate records of the blades history (# of flights etc.) is required

to extract any value from the test data.

We welcome your contributions to this effort.

Copyright © 2006 by Tech Model

Products LLC. • All Rights Reserved |